About Skycut

Production System

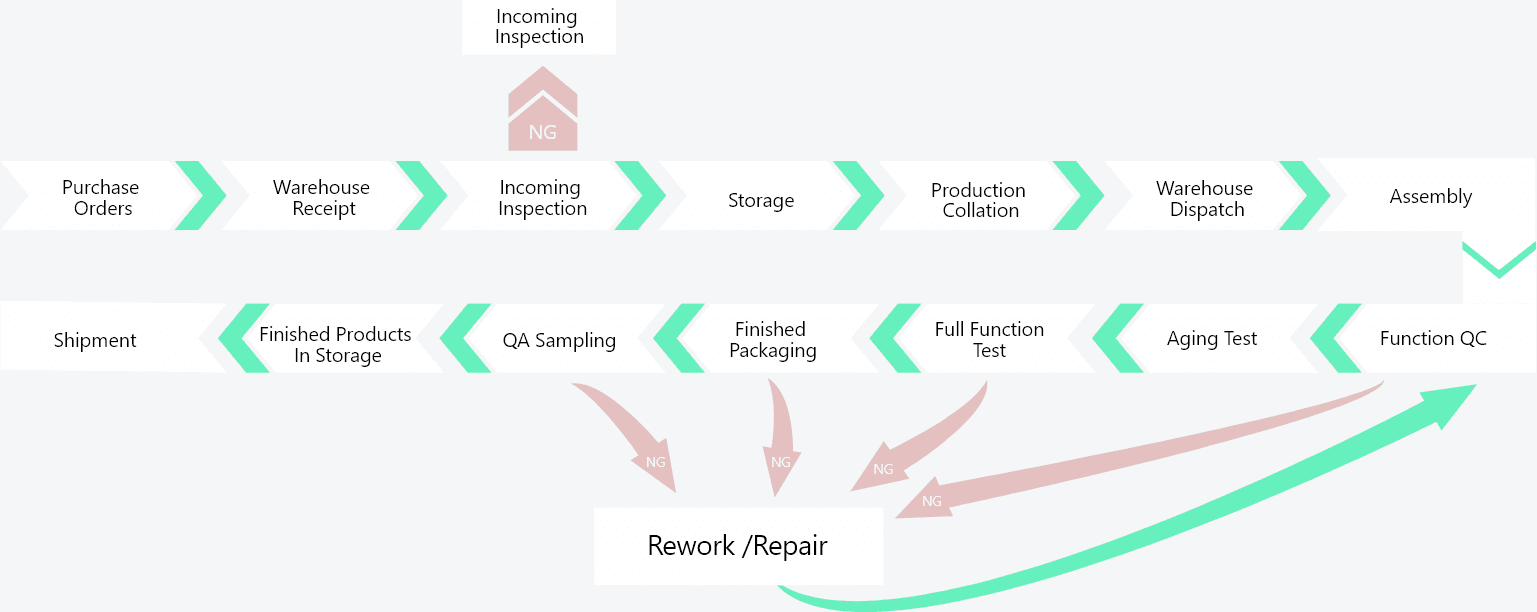

Refined Production System:

Ensuring Superior Quality and Efficient Supply Chain Management for Cutter Machines

Warehouse management

Efficient Warehouse Management

Ensuring Order and Quality Control

At SKYCUT, we have implemented an advanced three-dimensional warehouse system, designed to optimize space utilization and exceed the capabilities of traditional warehouses. With our unwavering commitment to qualified storage practices, only materials that pass our rigorous inspections are allocated to designated fixed storage positions, ensuring the segregation and integrity of each cutting machine component. Adhering to the principle of "first-in, first-out" and consistent accounts, we prioritize the use of materials based on their entry time, ensuring their applicability and freshness. Furthermore, we conduct regular quality checks to maintain the highest standards of performance and reliability for our cutting plotter machines.

Quality storage

Regular inventory

Storage division

Regional division

First-in First-out

Consistent accounts

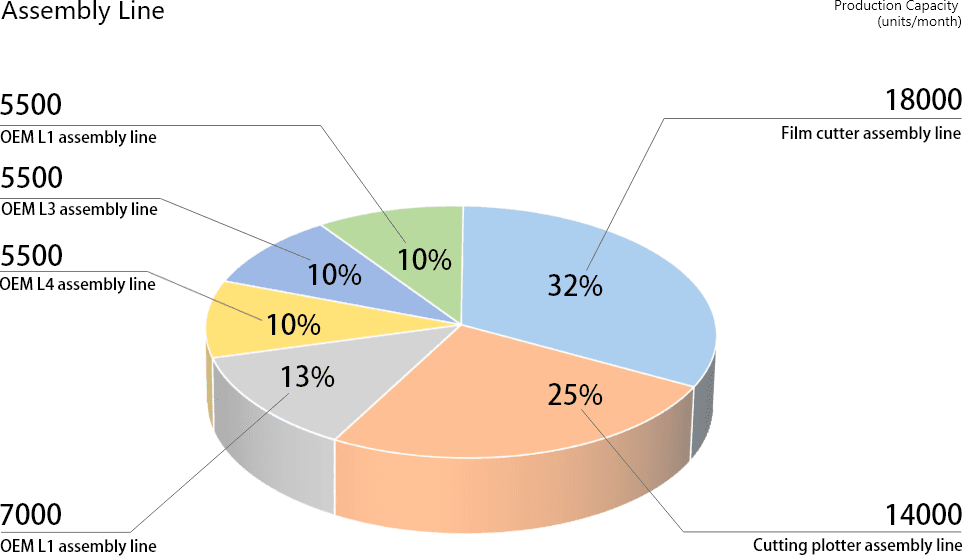

Capacity advantages:

Core Skilled workers

R&D Staffs

RMB 30 Million+

Productivity advantages:

Fast Response

Fast Delivery

And Packaging - 15 Days

Flexible Space

Time To Port - 2 Days

Production link:

Core Objectives

And Exceed Their Expectations